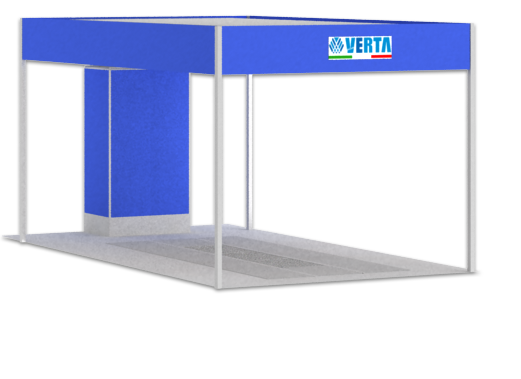

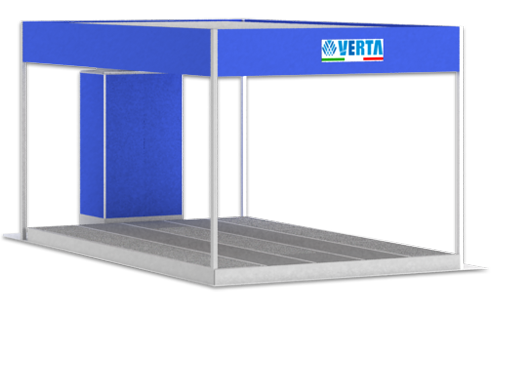

Smart Repair Booths and Preparation Areas

Like all Nova Verta heated spray booth systems, CTOFs and Limited Finishing Workstations use three distinct operating modes to maximize the energy efficiency of the complete painting process. Nova Verta is one of the first and few that have a listing allowing recirculation of the make up air system during preparation and cure cycles (re-circulation with direct fired heaters is not permitted per ANSI Standards or ETL on open type models). This allows for a substantial amount of fuel and electrical savings, since many of these systems are typically operated in re-circulation 60 to 75% of the time. The only time the system is required to be in full exhaust mode is during paint application. Re-circulation can save thousands of dollars and should carefully be evaluated before purchasing. Another advantage afforded by re-circulation is faster drying times.

Preparation Stations

Using a variable frequency drive and make-up unit with a stainless steel heat exchanger, the Nova Verta system warms air and safely recirculates it through the Prep Station – without exposing operators or other shop employees to the dangers of carbon monoxide. No other prep station or paint booth provides a prep cycle that creates OSHA-mandated working conditions, heats the air, maintains air pressure, brings metal to the desired spray temperature, and generates monthly utility savings of 35% or more when compared to competitive systems in its class.

S SERIES

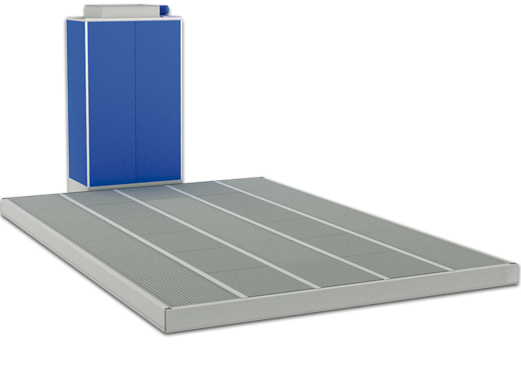

Pit style with gratings mm 3.960×2.220

Gratings with filters and underfilters meshes

Dry Exhaust Unit type “EE1“

N°1 electric motor of Kw 5,5 o 7,5

N°1 Centrifugal fan

Control Panel ON/OFF

Raised metal basement grating/checkered plate mm 6.140×3.680×400(h)

N°2 Ascent Ramps

Dry Exhaust Unit type “EE1“

N°1 electric motor of Kw 5,5 o 7,5

N°1 Centrifugal fan

Control Panel ON/OFF

Back flow: mm 3.700×1.040×680(h)

Dry Exhaust Unit type “EE1“

N°1 electric motor of Kw 5,5 o 7,5

N°1 Centrifugal fan

Control Panel ON/OFF

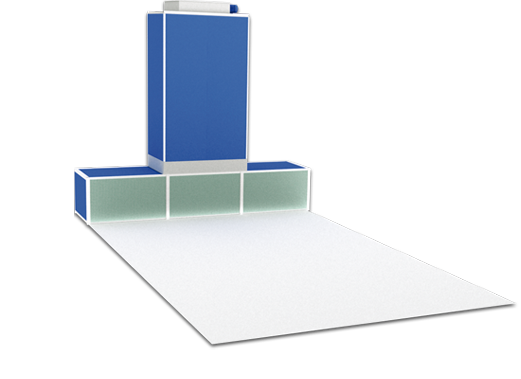

APP1 SERIES

Pit style with gratings: mm 3.960×2.220

Gratings with filters and underfilters meshes

Filtering plenum: mm 5.940×2.400 with bearing structure

N° 8 flat lighting fixtures with N° 4 neon tubes of 36 Watt each

Dry Exhaust Unit type “EE1“

N° 1 pneumatic by-pass for air recycle

Control Panel

Raised metal basement: mm 6.140×3.680×400(h)

Filtering plenum: mm 5.940×2.400 with bearing structure

N° 8 flat lighting fixtures with N° 4 neon tubes of 36 Watt each

Dry Exhaust Unit type “EE1“

N° 1 pneumatic by-pass for air recycle Control Panel

Back flow: mm 3.700×1.040×680(h)

Filtering plenum: 5.940×2.400 with bearing structure

N° 8 flat lighting fixtures with N° 4 neon tubes of 36 Watt each

Dry Exhaust Unit type “EE1“

N° 1 pneumatic by-pass for air recycle

Control Panel

APP2 SERIES

2 pit style with gratings: mm 3.960×2.220

Gratings with filters and underfilters meshes

N° 2 Filtering plenum: mm 5.940×2.400 with bearing structure

N° 16 flat lighting fixtures with N° 4 neon tubes of 36 Watt each (to. 64 neon)

N° 2 Dry Exhaust Units type “EE1“

N°2 by-pass for air recycle

Control Panel

Raised metal basement grating plate mm 6.140×3.680×400(h)

2 Filtering plenum: mm 5.940×2.400 with bearing structure

N° 16 flat lighting fixtures with N° 4 neon tubes of 36 Watt each (tot. 64 neon)

N° 2 Dry Exhaust Units type “EE1“

N° 2 pneumatic by-pass for air recycle

Control Panel

Back flow: mm 3.700×1.040×680(h)

Filtering plenum: (2x) mm 5.940×2.400 with bearing structure

N° 16 flat lighting fixtures with N° 4 neon tubes of 36 Watt each (tot. 64 neon)

N° 2 Dry Exhaust Units type “EE1“

N° 2 pneumatic by-pass for air recycle

Control Panel

MAKE-UP UNITS

Here you can create the content that will be used within the module.

18.000m³/h

1 elect. motor of Kw 5,5 (Hp 7,5)

1 centrifugal fan

Stainless steel heating exchanger

Oil burner

32.000m³/h

2 electric motor of Kw 5,5 or 7,5

2 centrifugal fans

Stainless steel heating exchanger

Oil burner

24.000m³/h

1 electric motor of Kw 5,5 or 7,5

2 centrifugal fans

Stainless steel heating exchanger

Oil burner

40.000m³/h

2 electric motor of Kw 7,5

2 centrifugal fans

Stainless steel heating exchanger

Oil burner

EXHAUST UNITS

18.000m³/h

1 eletric motor of Kw 5,5 or 7,5

1 centrifugal fan

Damper mm 600×600

Control panel ON/OFF

32.000m³/h

2 eletric motor of Kw 5,5 or 7,5

2 centrifugal fans

Damper mm 1000×1000

Control panel ON/OFF

24.000m³/h

1 eletric motor of Kw 5,5 or 7,5

2 centrifugal fans

Damper mm 800×800

Control panel ON/OFF

40.000m³/h

2 eletric motor of Kw 7,5

2 centrifugal fans

Damper mm 1000×1000

Control panel ON/OFF

Questions? Quotes? Please click the button below

Drop us an Email anytime and our customer service team will respond to you as soon as possible